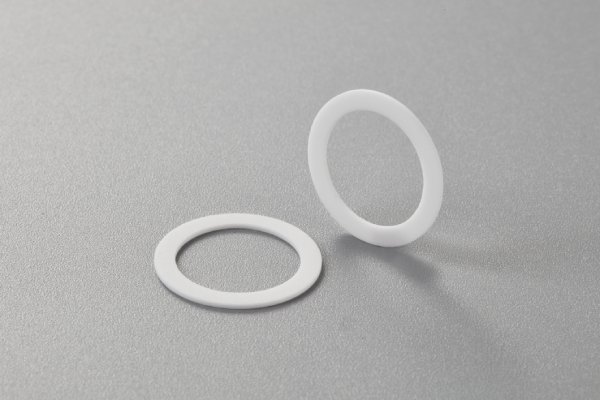

Alumina (aluminum oxide, Al₂O₃) Rings

Alumina rings are precision-engineered ceramic components made from high-purity aluminum oxide (Al₂O₃). They are widely used in industries such as semiconductor manufacturing, medical devices, aerospace, and industrial machinery due to their excellent thermal, electrical, and mechanical properties.

Key Features:

- High Hardness: Alumina rings are extremely hard, making them resistant to abrasion and wear.

- Thermal Stability: They can withstand high temperatures (up to 1600°C or more) without degrading.

- Electrical Insulation: Alumina is an excellent electrical insulator, even at elevated temperatures.

- Chemical Resistance: Alumina rings are resistant to most chemicals and corrosive environments.

Alumina Rings Specifications

| Item | Test condition | Unit | 96% alumina ceramics | 99% alumina ceramics | 99.5-99.7% alumina ceramics |

| Chemical ingredients | Al2O3 | Al2O3 | Al2O3 | ||

| Bulk Density | g/cm3 | >3.6 | 3.88 | 3.90 | |

| Max. Use Temp. | 1450℃ | 1600℃ | 1650℃ | ||

| Water absorption | % | 0 | 0 | 0 | |

| ROHS Hardness | ≥85 | ≥89 | ≥89 | ||

| Flexural strength | 20℃ | Mpa(psix10^3) | 358(52) | 550 | 550 |

| Compressive Strength | 20℃ | Mpa(psix10^3) | 2068(300) | 2600(377) | 2600(377) |

| Fracture Toughness | K(l c) | Mpa m^1/2 | – | – | – |

| Coefficient of thermal expansion | 25-1000℃ | 1X10^-6/℃ | 7.6 | 7.9 | 8.2 |

| Coefficient of thermal conductivity | 20℃ | W/m.K | 16 | 17-30.0 | 17-30.4 |

| Thermal Shock Resistance | ^Tc | ℃ | 250 | 200 | 200 |

| Dielectricity constant | 1MHz.25℃ | 9 | 9.7 | 9.7 | |

| Dielectric strength | ac-kV/mm(ac V/mil) | 8.3(210) | 8.7(220) | 8.7(220) | |

| Volume Resistivity | 100℃ | ohm-cm | >10^13 | >10^14 | >10^14 |

Alumina Rings Applications

- Seals and Bearings: Used in pumps, valves, and machinery due to their wear resistance and ability to operate in harsh environments.

- Electronics: Serve as insulating components in electronic devices, such as sensors, capacitors, and high-voltage equipment.

- Thermal Management: Used as thermal insulators or spacers in high-temperature environments.

- Medical Devices: Utilized in implants, prosthetics, and surgical tools due to their biocompatibility and durability.

- Laboratory Equipment: Used in high-temperature furnaces, reactors, or as sample holders.

- Semiconductor Industry: Employed as wafer carriers or process components in semiconductor manufacturing.

Payment & Order Questions

Most Popular Questions

We offer alumina rings in various purity grades, including:

96% Alumina (cost-effective for general applications)

99.5% Alumina (high-purity for demanding environments)

99.8% Alumina (ultra-high-purity for critical applications)

Yes, we provide custom manufacturing services to meet your exact specifications, including inner/outer diameters, thickness, and surface finishes. Contact our team for a quote.

Alumina rings offer a unique balance of properties, including higher hardness and better wear resistance than zirconia, and better thermal stability than polymers. They are also more cost-effective than advanced ceramics like silicon carbide or aluminum nitride.

We offer a range of surface finishes, including:

As-fired (standard finish)

Polished (for reduced friction and improved aesthetics)

Lapped (for ultra-precise dimensions and tight tolerances)

Yes, high-purity alumina (99.5% and above) is biocompatible and widely used in medical and dental applications, such as implants and surgical tools.

We offer flexible MOQs to accommodate both small-scale prototyping and large-scale production needs. Contact us for specific details.

Yes Sure, we can provide Alumina Ceramic Samples According to Your Requirements.

Our lead time for orders typically ranges from 4 to 8 weeks, depending on the product and order size. For specific timelines, please contact us directly.