Ceramic Metallization

What's Ceramic Metallization ?

Ceramic metallization is the process of applying a metallic layer to ceramic surfaces, enabling them to bond with metals, enhance electrical conductivity, or improve thermal performance. It is widely used in electronics, aerospace, and medical devices. Common ceramics include alumina, zirconia, and silicon nitride, while metals like molybdenum, tungsten, and nickel are typically used.

Key processes include thick film, applying metal pastes and firing; thin film, using sputtering or vapor deposition; and active brazing, bonding ceramics and metals directly. Steps involve surface preparation, coating application, and heat treatment.

Applications include semiconductors, sensors, and high-power microwave devices. Ceramic metallization offers robust bonds, thermal resistance, and high durability, making it vital for high-performance engineering. It integrates the insulating properties of ceramics with the conductivity and malleability of metals, enabling advanced technologies in various industries.

Materials For Ceramic Metallization

| Material | Thermal Conductivity (W/m·K) | Coefficient of Thermal Expansion (10^-6/K) | Key Characteristics |

|---|---|---|---|

| Alumina (Al₂O₃) | 20-30 | 6-8 | High hardness, excellent electrical insulation, and thermal stability. Widely used in metallization due to its compatibility with thick-film and thin-film processes. |

| Aluminum Nitride (AlN) | 150-200 | 4-5 | High thermal conductivity, low thermal expansion, and excellent electrical insulation. Ideal for high-power applications requiring efficient heat dissipation. |

| Beryllia (BeO) | 200-300 | 6-8 | Extremely high thermal conductivity, but toxic in powder form. Used in specialized high-power applications. |

| Zirconia (ZrO₂) | 2-3 | 8-10 | High fracture toughness, low thermal conductivity, and excellent thermal shock resistance. Used in applications requiring mechanical durability. |

| Silicon Nitride (Si₃N₄) | 20-30 | 2-3 | High strength, excellent thermal shock resistance, and moderate thermal conductivity. Suitable for harsh environments. |

| Steatite (MgSiO₃) | 2-3 | 7-9 | Good electrical insulation, moderate thermal conductivity, and cost-effective. Used in low to medium-performance metallization applications. |

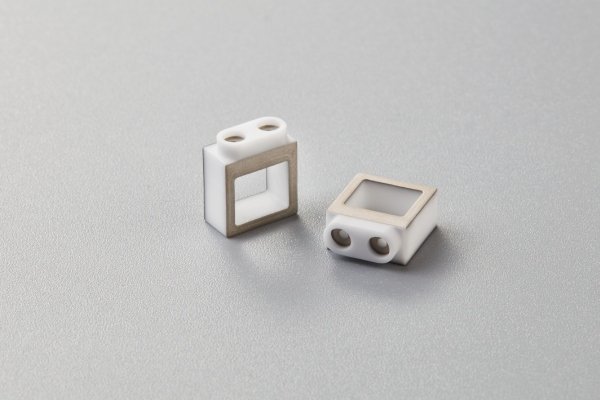

Wide Range of Ceramic Metallization Parts

Discover our Diverse Range of Ceramic Metallization Parts, designed to meet the demands of advanced industries. From ceramic-to-metal bonding components to hermetic seals, our products ensure unmatched thermal, electrical, and mechanical performance. Crafted from high-purity ceramics like alumina and zirconia, with precision-applied metal coatings such as molybdenum-manganese and nickel plating, these parts excel in high-temperature, high-voltage, and vacuum applications. Ideal for aerospace, electronics, medical, and power systems, our metallized ceramics deliver reliability, durability, and customization for your most critical projects.

Table of contents

Tell us your requirements, and we will custom design ceramic parts that meet your needs.

What Set Ceramitechforge Apart ?

Larger Capacity,Better Price

Take advantage of our annual 5 million industrial ceramics. Reliable supply, high quality, and timely delivery to enhance competitiveness

OEM/ODM Services

We provide custom industrial ceramics tailored to diverse applications, ensuring superior quality, reliability, and performance in your specific industry.

Factory Direct Price

Access unbeatable savings with direct-from-factory pricing, ensuring a competitive edge and cost efficiency for your business.

Certificated Quality

Guaranteed excellence with certified quality, ensuring reliability and customer satisfaction for your brand and business.

Fast Delivey in 5 Days

Experience rapid fulfillment with our 5-day delivery, keeping your supply chain efficient and customers satisfied

24hx7 Engineer Support

Ensure seamless production with 24/7 engineer support, providing quick resolutions and maintaining operational efficiency

See to Believe

Our Advanced Industrial Ceramic Factory

Step05: Load Blanks on Ceramic

Step06: Sintering Process

Step07: Vibratory Washing

Step08: Warehouse & Logistics

Why Choose Ceramicforge ?

As a leading OEM/ODM Industrial Ceramics manufacturer based in China Ning Bo. With 20 years of dedicated expertise, our factory specializes in innovative, patent-backed Industrial Ceramic solutions. We excel in OEM services, allowing customization to fit your project requirements precisely. Annually producing over 50 million units, we ensure each product integrates cutting-edge technology with eco-friendly efficiency. Our ISO9001, ISO14001, CE, certifications testify to our commitment to quality. Partner with Ceramitechforge to benefit from our advanced manufacturing capabilities and drive your projects with superior, sustainable Ceramic solutions.

- 20 Years Expertise

- ISO14001,ISO9001,CE Certified

- 50 Million Cermics Per Year

- 400+ Skillful Workers

- 24h x7 Online Support

Our Workflow

What is Our Leads Time ?

Step 1: Product Design Communication (3-7 days)

Collaborate closely with our design experts to transform your vision into reality. Our streamlined communication ensures your specifications are met precisely, resulting in bespoke industrial ceramics tailored to your brand’s unique requirements, enhancing your product line and competitive edge.

Step 2: Engineer Ceramic Sampling (7-14 days)

Receive meticulously engineered ceramic samples for evaluation. This process guarantees that our products meet your quality standards before bulk manufacturing, allowing you to make informed decisions, minimize risks, and ensure the final product aligns perfectly with your needs

Step 3: Pay The Bill (within 1 day)

Streamline your project timeline with our efficient payment process. Completing your payment within one day ensures there are no delays, so we can move forward quickly with manufacturing your Industrial Ceramics.

Step 4: Bulk Manufacturing (30-45 days)

Benefit from our state-of-the-art manufacturing facilities capable of producing high-quality industrial ceramics in large volumes. Our efficient production processes ensure timely delivery, helping you meet market demands and maintain a steady supply chain.

Step 5: Shipping (10-15 days)

Enjoy reliable and timely shipping services that ensure your products reach their destination safely and on schedule. Our comprehensive logistics support minimizes delays and enhances your ability to meet customer expectations and market demands effectively.

Want to know how to compress lead times?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy industrial ceramics experience.

Payment & Order Questions

Most Popular Questions

We use high-performance ceramics such as alumina or zirconia, combined with metallic coatings like molybdenum-manganese (Mo-Mn), nickel, or silver for excellent conductivity and bonding properties.

Our metallized ceramics provide high thermal stability, superior insulation, and excellent electrical conductivity, ideal for demanding environments.

Yes, we can supply certifications such as ISO, RoHS, CE, and other specific test reports upon request.

Our minimum order quantity (MOQ) varies depending on the product type. Please contact us for specific requirements.

Metallized ceramics are widely used in industries such as aerospace, medical devices, electronics, telecommunications, and power systems.

Absolutely. We offer custom designs, including specific dimensions, shapes, and metallization patterns, to fit your application.

We perform adhesion tests, thermal cycling tests, and electrical conductivity checks to ensure product reliability.

Our lead time for orders typically ranges from 4 to 8 weeks, depending on the product and order size. For specific timelines, please contact us directly.

Contact to Get Free Sample

What's our customer's Opinion?